03. TEST-BENCH

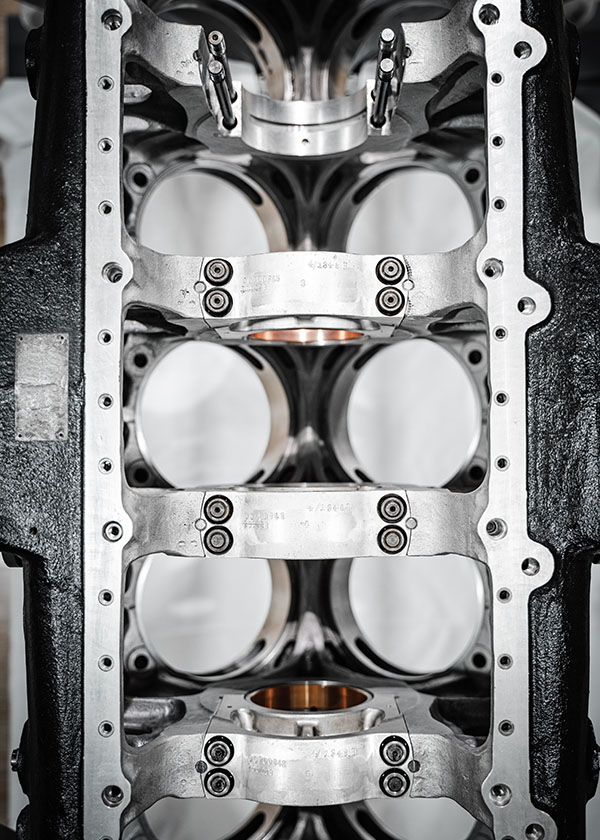

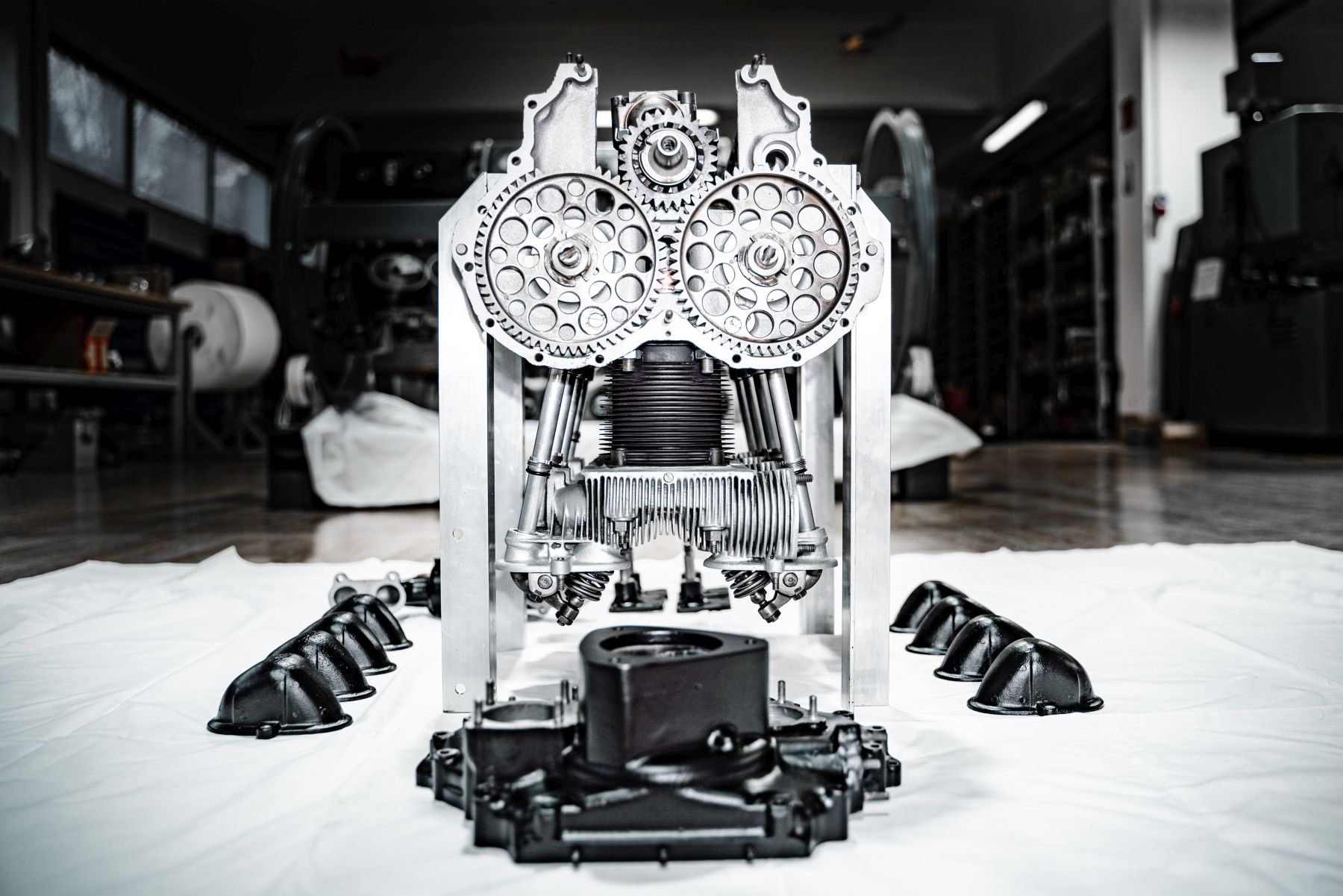

In 2019 we established our own in-house testbench. We can run aircraft piston engines in stationary and dynamic conditions. We can cover a wide range of engines – from a 2-liter Zündapp up to a 36-liter DB605.

The setup for the testbed (cooling-system, adjustment of propeller for testbench use, installation of measurement devices) is done in house.

We can measure a wide range of engine parameters such exhaust-gas temperatures, intake air temperature, intake manifold pressure, oil and water temperature, oil-pressure, fuel consumption and temperature, pitch-cpntrol, oil consumption, torque and engine speed and ambient- pressure and temperature with a 10Hz recorder. We also “film” the test-runs with 4 cameras from different positions.

During the testrun, the testbed controller can adjust speed and load according to the test program. In parallel all data from the measurement devices are transferred to the control-stand – so we can check in real time what is happening.

This gives us the opportunity to check the engine behavior before the engine is built in the aircraft. Based on these results, we can make adjustments on the engine and document a detailed status.

Besides engines, that we build in-house, its also possible to run “external” engine on our testbed. Depending on the project-boundaries, we can do the test-bed and engine set-up and support the runs-itself. The data-analysis and eventual adjustments on the engines, can be done by the customer.